{Catering to stringent standards of deep-freeze applications demands highly specific valve technology. Our enterprise’s freezing 3-way circular instrument options are designed to provide reliable productivity even at ice-cold temperatures, typically below -150°C. These units offer superior flow supervision in condensed materials such as nitrogen, oxygen, and argon, frequently adopted in arenas like LNG, academic equipment, and biomedical facilities. Our group value resilient construction, including slip-resistant gasket ingredients and accurate forming, to confirm hermetic performance. Contemplate the advantages of boosting your arctic system with our innovative 3-way globe-shaped valve options.

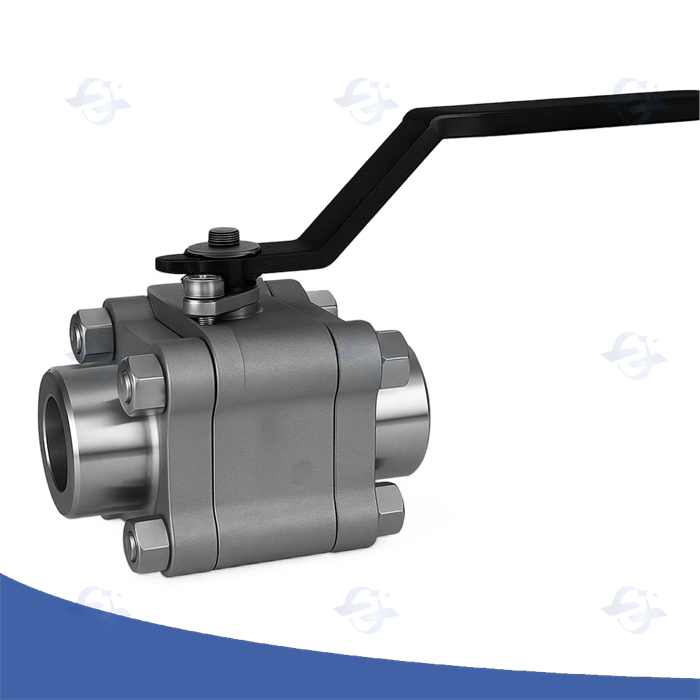

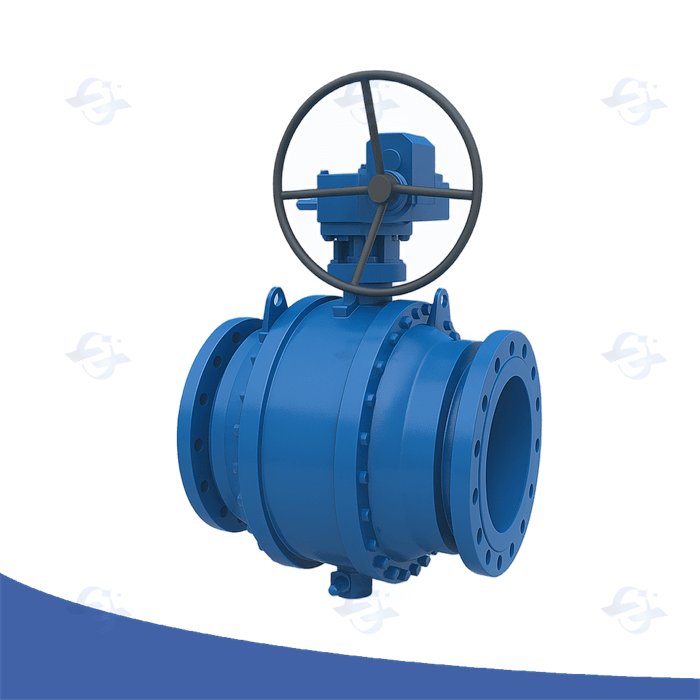

Top-Quality Dual Closure and Drain Sphere Valve Units

In terms of crucial applications, particularly where spillage is taboo, top-tier double block and bleed rotational valves offer distinctive assurance. This innovative design incorporates two autonomous disk valve seals, additionally a bleed vent, allowing for corroboration of the perfect shut-off and identification of any conceivable leakage. Generally employed in fuel workflows, chemical processing, and cryogenic situations, these valves significantly enhance productive stability and lower the likelihood of ecological influence.

Tri-Path Chilling Rotary Valve Design

This creation of tri-directional frosty orbital device presents a singular engineering issue. These components are frequently employed in essential industrial implementations where drastic heat levels must be preserved. Key matters include substance preference, primarily regarding fragility at reduced conditions, and the essentiality for tight stopping to halt draining of ice-cold liquids. Innovative study styles and meticulous assembling routines are fundamental to guarantee consistent output and permanence under such strict engaging locations.

Arctic Actuator Efficiency in Process Applications

These demanding prerequisites of chilly applications, such as subzero natural gas handling and cryogenic nitrogen storage, necessitate steady valve techniques. Integral block vent instruments provide a particularly robust and effective approach to achieving zero-leak barrier while facilitating routine maintenance. Their design contains a primary control device with a small escape path, allowing directed pressure escape during stopping and reengagement. This inherent quality minimizes persisting content entrapment, thereby ensuring exceptional shielding and effectiveness even under the most harsh engaging cases. Furthermore, the ability to observe vent circulation provides valuable examination facts for workflow advancement.

Ensuring 3-Way Globular Valve Sealing in Demanding High-Pressure Environments

Achieving solid stopping performance with 3-way globular valves becomes particularly noteworthy when operating within intense pressure situations. The design must account for significant impacts and potential seepage pathways. Specialized compositions, often including high-performance metals like long-lasting steel or exotic alloys, are vital to endure the stringent conditions. Furthermore, sophisticated connection geometries and fine development processes are crucial to minimize bending and guarantee a sealed coupling even under fluctuating pressure cycles. Regular review and maintenance servicing programs are moreover vital for longevity and sustained operational trustworthiness.

Freezing Ball Valve Leakage Prevention Strategies

Limiting "oozing" from cryogenic "ball valves" demands a multifaceted "technique". Initial "blueprint" considerations are paramount; material "decision" must account for extreme "heat extremes" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "constituent", meticulous "creation" processes – including stringent weld "evaluations" and non-destructive "testing" – are vital to ensure structural integrity and eliminate voids that could become "leakage paths". A "critical" component is proper "configuration"; thermal "contraction" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "upkeep" – including periodic "examination" for signs of wear and "rectification" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "schedule" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "depletion", safety "hazards", and costly "pause”.

Paired Seal and Exhaust Component Verification Systems

To secure the integrity and safety of critical piping lines, rigorous coupled block and discharge mechanism evaluation plans are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation apparatuses while simultaneously ensuring the release tool remains functional and correctly discharges any trapped gas. A common process is to utilize a pressure analysis where the system is pressurized to its maximum working pressure, and the seepage rate around the closed units is meticulously checked. The discharge device's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of trial results, including any discrepancies observed, is required for maintaining a reliable procedure.

Comprehending Whole Block Discharge Apparatus Work

With the aim to successfully supervise load structures, a extensive comprehension of integral block vent tool operation is undeniably necessary. These specific parts primarily work to reliably discharge superfluous load from a system during appointed operational phases. A conventional placement features a fitted chamber associated to the leading pressure source, facilitating such supervised discharge upon necessary. The innate structure curtails the danger of beyond-limit pressure, protecting both the gear and the adjacent setting. Regular review and repair are imperative to safeguard best output.

Deciding on the Fitting 3-Way Ball Valve for Cryogenic Fluids

Deciding on a apt 3-way-ball tool for cryogenic implementations demands careful review of several critical criteria. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present atypical challenges. Material picking is paramount; only materials with proven compatibility and ductility at these temperatures, such as hardened steel grades like 304L or 316L, or specialized non-ferrous alloys, should be evaluated. Furthermore, the valve's sealing capacity is vital to prevent emissions, requiring expert stem sealing patterns and low-temperature solutions. Finally, pressure indications and actuation methods, taking into account potential pressure jumps, must be carefully matched to the system's specifications. Neglecting these elements can lead to catastrophic failure and safety threats.

Chilled Round Valve Compound Suitability Handbook

Identifying the appropriate material for cryogenic circular valves is paramount, given the critical temperatures involved. This reference highlights common compounds and their reaction when exposed to cryogenic fluids such as media nitrogen, media helium, and oxygen. Stainless steels, particularly kinds 304 and 316, often demonstrate adequate sturdiness and deterioration resistance, though martensitic alloys require careful consideration regarding delicacy. Aluminum alloys can be suitable for certain applications, however, their bendability and endurance to specific chemicals needs exhaustive evaluation. Copper alloys, while offering some strengths, may exhibit subdued productivity at these diminished temperatures. Consultation with vendors and comprehensive review is essential to validate endurance and reliability in cryogenic processes.

Improving DBB Framework Effectiveness

Achieving optimal work in dual block and bleed constructions hinges on a multifaceted procedure. Careful examination of part selection is necessary, with a focus on material correspondence and tension rating. Regular check of release avenues for blockage is indispensable, often involving the use of dedicated assessment devices. Furthermore, process advancement—including assessment of transfer rates and compression variation—can dramatically improve overall construction durability and safeguarding. Finally, observance to supplier guidelines and the application of a rigorous preservation plan are critical for long-term performance and longevity.

cryogenic ball valves manufacturers

cryogenic ball valves manufacturers